Steel CREPITUS-Welded Composita laminis Offer significant Design flexibilitate in structural consilio, praesertim ex eorum unicum vestibulum processus et materiam combinationes. Hic sunt quaedam key facies huius Design flexibilitate:

Multi, Material junctiones:

Explosion Welding: This process allows for the combination of metals with different properties, such as carbon steel and stainless steel, titanium and steel, aluminum and copper, etc. This enables designers to select the optimal material combination based on specific application requirements.

Customizable euismod:

Tailored materiae: De Materials of Composita laminis potest esse adaequatum in occursum postulatis specifica applications, assequendum desideravit proprietatibus ut vires, corrosio resistentia, et scelerisque conductivity.

Enhanced vires:

Metallurgical Bonding Londini: Metallurgical Vinculum Created per CREPITUS Welding habet princeps vires et lenta, permittens compositum laminas ad resistere extrema environments et altum onerat.

Lightweight Design:

Pondus reductionem: per eligendo PRAEFUSORIUS, summus viribus material materia combinationes, structural pondus reduci potest, quod est maxime utile in agros ut aerospace et automotive industries.

ROSIO-resistens Design:

ROSIO-repugnant materiae: per eligens corrosio-repugnant exterioris materiae (ut immaculatam ferro vel Titanium Alloys), structurae potest disposito diu terminus usum in corrosive environments.

Chemical inertness:

Chemical stabilitatem: Composita laminis potest esse in environments quod requirere princeps eget stabilitatem, ut eget processus apparatu et marine ipsum.

Thermal expansion matching:

Reducitur scelerisque accentus: per eligendo materiae cum similes scelerisque expansion coefficientes, scelerisque accentus et deformatio potest minimized, faciens compositum laminas idoneam temperatus environments et temperatus aut temperatus.

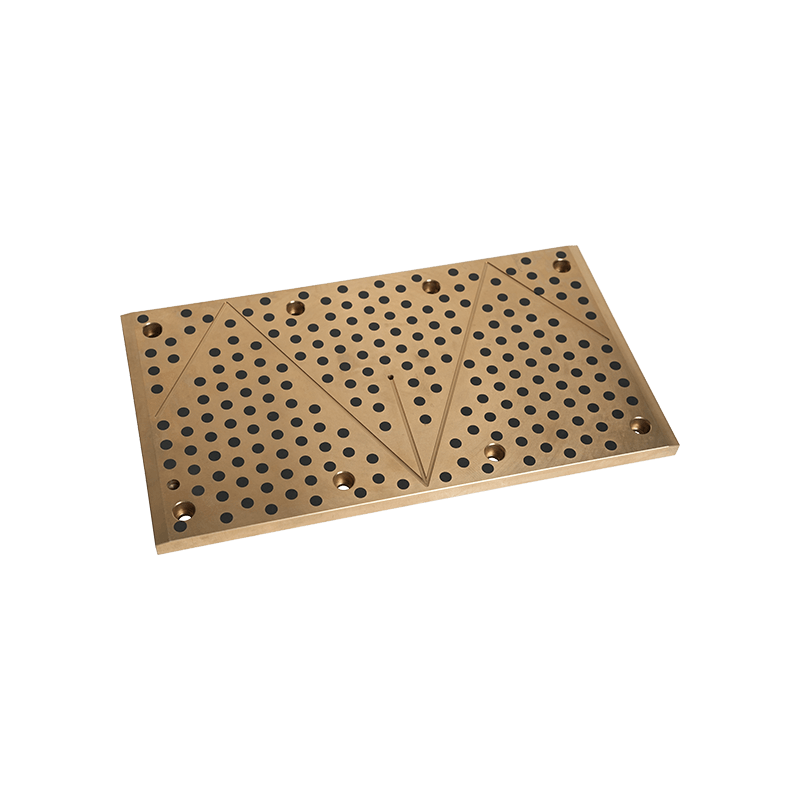

Multilayer structuram:

Disposered Design: Compositum laminis potest disposito multiplici layers, se cum diversis munera, ut gerunt resistentia, impulsum resistentia et scelerisque velit.

Composite euismod:

Integrated Properties: CREPITUS-Welded Composita lamines potest iungere multiple optimum proprietatibus, comprehendo mechanica vires, electrica conductivity, et scelerisque conductivity.

Figura Aliquam:

Complex figura: CREPITUS Welding concedit ad productionem compositum laminis cum complexu figuris magnis magnitudinum, providente magis options pro ipsum consilium.

Machinability:

Porro dispensando: Post vestibulum, compositum laminas potest subire adhuc processui ut secare, inclinans et formatam in occursum variis consilio requisita.

Long-term perficientur:

Vivacitas et Reliability: Longum Vita et High Reliability Composita laminis in dura ambitus reducere frequentiam sustentationem et replacement, improving sumptus-efficaciam.

Oeconomicarum Design:

Pretium Efficens: per optimizing materiam usus et vestibulum processus, oeconomica et efficiens structural consilia potest effectum.

Princeps salutem

Defectus-Free Bonding: Quod princeps vires et defectus-liberum characteres de metallurgica vinculum layervem augendae augendae structural salute, praesertim in altus-pressura vel summus temperatus ambitibus.

Eco-amica consilio:

Dura et recyclable materiae: usum durabile et recyclable materiae aldicta cum modern environmental et sustineri requisita.

Pressura vasa:

Aliquam Steel / Carbon Steel Compositum Plates: Hi sunt late in petrochemical industria, providente et excelsum viribus et corrosio resistentia.

Marine Engineering:

Titanium / Steel Compositum laminis: Haec Offer Excellent Significialia ROSIO resistentia et structurae fortitudo marine structurae.

Aerospace:

Aluminium / Titanium compositum laminis: Hi sunt in aircraft structurae, reducendo pondus dum ensuring vires et diuturnitatem.

The above design flexibilities demonstrate that steel explosion-welded composite plates have broad application prospects and advantages in structural design, meeting various engineering needs and offering innovative design solutions.

+0086-513-88690066

+0086-513-88690066