Et corrosio resistentia Aeris Alloy Series Influended per plures key factores, comprehendo alleo compositionem, environmental conditionibus et materiam proprietatibus. Hic 'a detailed Overview de factoribus, qui afficiunt ad corrosio resistentia aeris alloys:

Elementa additum est aeris creare Alloys significantly impulsum corrosio resistentia:

In aere, moles zinc afficit corrosio resistentia. Maximum cadmiae contentus potest ad dezincification, ubi cadmiae leed ex, relicto raro aeris structure.in aes, stagnum improves resistentia ad corrosionem, praecipue in marine environments. Phosphoras aes, quae etiam habet phosphoro, enhances gerunt resistentia et corrosio resistance.adding nickel (ut in aeris-nickel Alloys) amplio et dura et corrosio, praesertim in maris, aluminium et excelsum leatigatos et inauguralis aes, plumbum amplio, et plumbum amplectitur, inter se maris, plumbum amplectitur, et plumbi Machinability sed potest reducere altiore corrosio resistentia.

Aeris Alloys plerumque resistere dulcis corrosio bene, sed quidam Alloys ut adhuc experiri exitibus sicut pitting aut corrosio, si patere infestantibus condictive conditions.copper-nickels Alloys et aluminium aureum praestare saltwater corrosio.

Resistentia aeris alloys ad acidic et basic environments variat. Nam exempli gratia, aes potest corrode magis celeriter in acidic condiciones comparari aes aut aeris-nickel alloys. Nuditate alchimicis sicut sulphure dioxide vel CHLORUM potest ad acceleratum corrosio. Alloys disposito industriae usum saepe habent proprietatibus ad tractamus his conditionibus.

High temperaturis potest afficiunt corrosio resistentia aeris alloys.can accelerate oxidation et mendade alloy properties.May non directe impulsum corrosio sed potest afficit materia perficientur et fragteless.

Et microstructure de stone, comprehendo distribution phases et praesentia praecipitat, influit eius corrosio resistentia. Uniform Microstructures plerumque offerre melius perficiendi.finer frumenti structurae augendae corrosio resistentia reducendo susceptibilitatem ad localized corrosio.

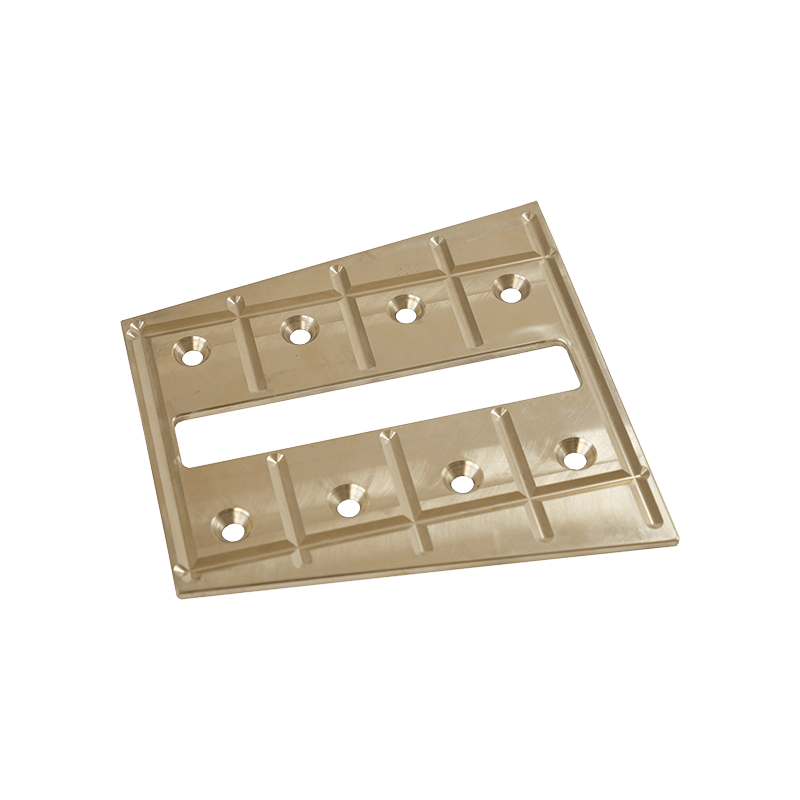

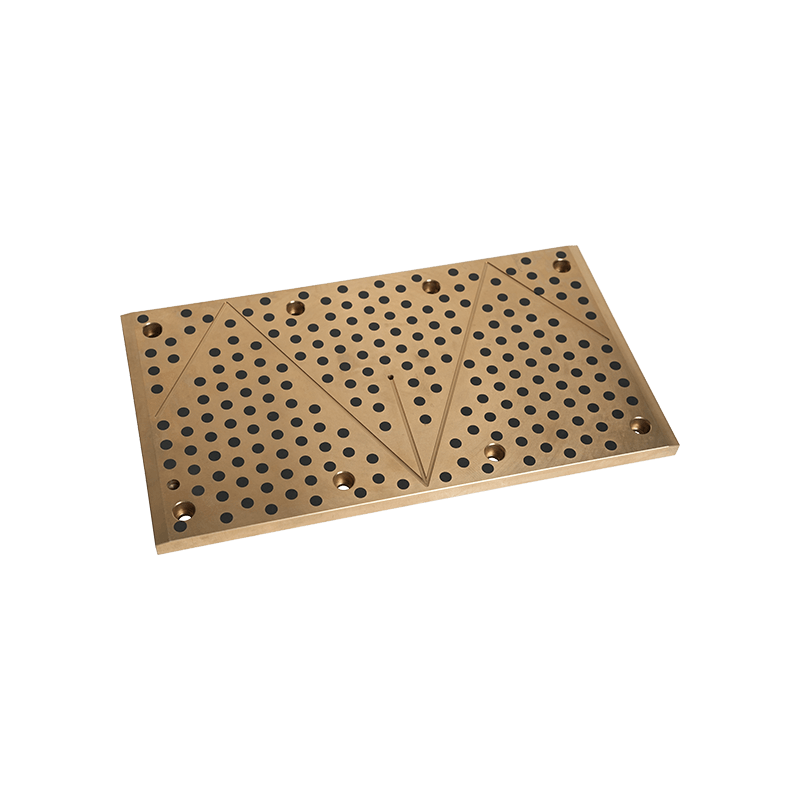

Smooth, bene esse superficies minus proni ad corrosio quam aspera aut laedi superficies. Superficies treatments et coatings potest providere additional protection.applying tutela coatings vel platings can scutum aeris alloys a infestantibus environments, enhancing eorum altiore corrosio resistentia.

Mechanica accentus aut iactabantur potest impulsum ad corrosionem resistentia aeris alloys. Accentus, corrosio fregisset potest fieri in aliquo alloys si subiecta ad trensile accentus in mordendo environments.cold operantes aut iactabantur indurare potest afficit stilo est susceptibilis ad accentus-related.

Et calor curatio processus potest influere ad corrosio resistentia aeris alloys afficiens microstructure et tempus compositionem modum fabricae potest inducere impudicitiis vel defectibus quae afficit corrosio resistentia. Propriis qualis imperium in productio iuvat ut melius perficientur.

Regular maintenance, including cleaning and inspection, can prevent the buildup of corrosive agents and extend the life of copper alloys.Using appropriate protective measures, such as coatings or inhibitors, can further enhance corrosion resistance in specific applications.

Elementa additum est aeris significantly impulsum corrosio resistentia. Nickel and aluminum enhance resistance, while zinc and lead can have mixed effects.Exposure to different environments, including water, chemicals, and temperature variations, influences corrosion performance.The alloy's microstructure and surface treatment play crucial roles in its resistance to corrosion.Stress and strain can affect corrosion resistance, particularly in stressed or strained conditions.Proper fabrication and regular maintenance are essential for Conservandam corrosio resistance.

+0086-513-88690066

+0086-513-88690066